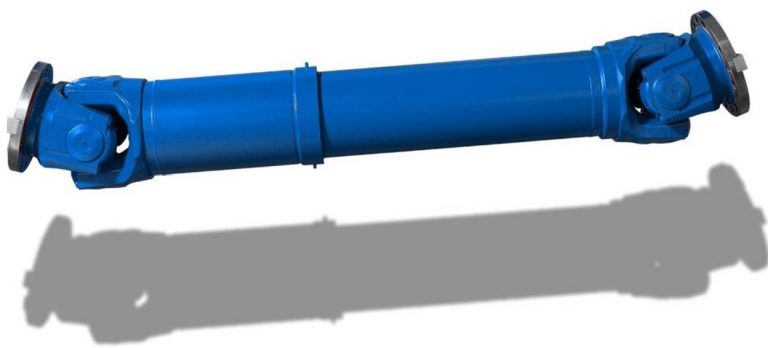

CARDAN SHAFTS - U-JOINTS - UNIVERSAL JOINT SHAFTS

GEWES Cardan Shafts, or even called u-joints, facilitate reliable torque transfer between spatially remote drive and output trains. Cardan shafts from GEWES offer suitable mechanical drive solutions in nearly all industrial sectors due to their versatile design and their high efficiency.

Our weight-optimised, energy-efficient, high-performance universal joint shafts are developed by using advanced methods and FEM calculations to provide optimal tube wall strengths and diameters for high torsion and bending resistance.

We use tempered steel and case-hardened steel for our u-joints. Calibrated precision steel tubes are used for particularly demanding solutions. All materials used fulfil the requirements for marine classification and rail vehicle applications. Reliable and continuous operation of our u-joints with a high torque capacity is therefore guaranteed. Our Cardan shafts are further characterised by low-maintenance components and low maintenance costs over the entire product life cycle.

Our dynamic balancing systems allow balancing of universal joint shafts with high accuracy to comply with the specifications for applications that involve fast-turning universal joints. Running with low vibrations reduces the load on the drive and the universal joints. This leads to a longer service life and creates less operating noise.

Our specialised staff will gladly help you find the right universal joint for your application or will develop a suitable solution according to your specific requirements.

Technical specifications

|

Series |

Limiting torque |

Alternating torque |

Swing diameter |

Flange connection |

Flange connection |

Flange connection |

Flange connection |

|

[Nm] |

[Nm] |

[mm] |

[mm] |

[mm] |

[mm] |

||

|

350 |

100 |

60 |

58/65 |

– |

– |

– |

|

|

1100 |

320 |

90 |

75/90/100 |

1120/1300 |

– |

– |

|

|

2400 |

1000 |

98 |

90/100/120 |

1120/1300/1400 |

100 |

– |

|

|

4200 |

1300 |

115 |

100/120/150 |

1400/1500 |

120 |

– |

|

|

6200 |

1700 |

125 |

120/150/165/180 |

1500/1600 |

120 |

– |

|

|

8800 |

2500 |

155 |

150/165/180 |

1600/1700/1800 |

152 |

– |

|

|

11500 |

4000 |

160 |

150/165/180 |

1600/1700/1800 |

152/180 |

– |

|

|

17000 |

5100 |

174 |

180/225 |

1800 |

– |

– |

|

|

21000 |

5100 |

170 |

180/225 |

1800 |

180 |

– |

|

|

25000 |

7300 |

178 |

180/220/225/250 |

1800/1880 |

180 |

– |

|

|

28000 |

11000 |

204 |

180/225/250 |

1880 |

180 |

– |

|

|

34000 |

– |

204 |

– |

– |

200 |

– |

|

|

33000 |

13000 |

215 |

225/250/285 |

1880/1900 |

– |

– |

|

|

40000 |

18000 |

250 |

250/285 |

1880 |

– |

– |

|

|

55000 |

23000 |

265 |

285 |

– |

– |

– |

|

|

55000 |

23000 |

250 |

250/285/315 |

– |

– |

– |

|

|

58000 |

24000 |

250 |

285/315 |

– |

– |

– |

|

|

120000 |

45000 |

285 |

285/315/350 |

– |

– |

– |

|

|

175000 |

58000 |

315 |

315/350/390 |

– |

– |

– |

|

|

200000 |

70000 |

350 |

350/390/435 |

– |

– |

– |

|

|

200000 |

70000 |

370 |

350/390/435 |

– |

– |

– |

|

|

55000 |

23000 |

225 |

225/250 |

– |

– |

225/250 |

|

|

105000 |

36000 |

250 |

285/315 |

– |

– |

250/285 |

|

|

150000 |

53000 |

285 |

315/350 |

– |

– |

285/315 |

|

|

215000 |

75000 |

315 |

350/390 |

– |

– |

315/350 |

|

|

260000 |

100000 |

350 |

390/435 |

– |

– |

350/390 |

|

|

370000 |

140000 |

390 |

435/480 |

– |

– |

390/435 |

|

|

600000 |

225000 |

435 |

– |

– |

– |

435/480 |

PRODUCT RANGE